DH-ROC is a modern inline flexo printing machine.

1、Sleeve technology, quick job change

Adopts sleeve technology of plate cylinder and anilox roller (optional) to achieve fast job change.

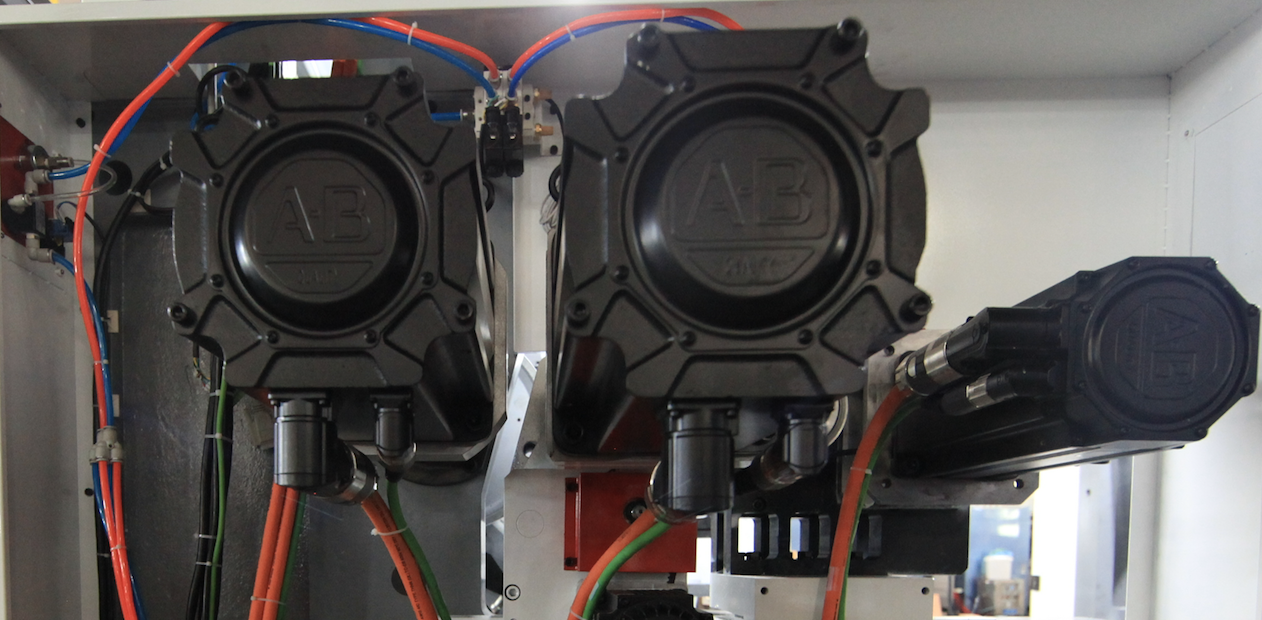

2、Gearless drive system

Each printing station is driven by 8 servo motor to avoid gear wearing when running at high speed.

Thanks to the gearless drive system, ROC has a great job repeatability. It can record and recall: register position, pressure setting, tension etc.

3、Turret auto splicing system

ROC adopts turret auto splicing system on unwinder and rewinder. The unique design can guarantee splicing stability.

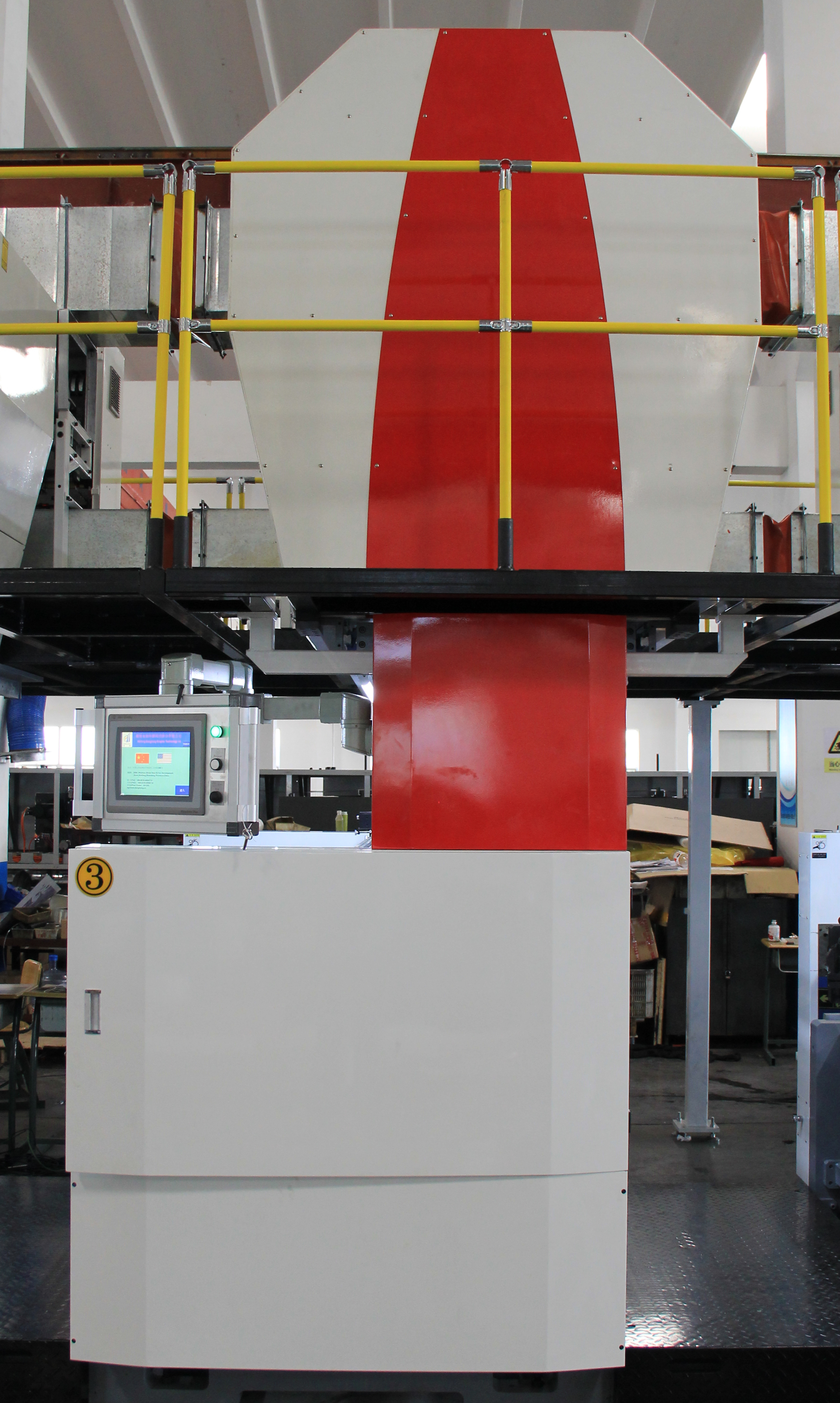

4、High efficiency hot air drying unit

After printing, substrate goes up and pass the high efficiency drying unit to achieve high running speed. Cover of drying unit can slid out for substrate threading and hot air is recycled to lower down power consumption.

5、Inline 100% quality inspection system

ROC adopts inline quality inspection system. Once defect is found, system will give an alarm and record relevant information.

6、Chamber inking system

The chamber doctor blade system can guarantee inking stability. Meanwhile, together with inline anilox roller cleaning system (optional), it can greatly lower down cleaning time and cost.

7、Intelligent control system

* Register position record/recall

* Printing pressure record/recall

* Tension record/recall

* Pre-register function

* Pressure compensation when running at high speed.

* Inline quality inspection system

* Auto register system

* Closed-loop tension control

Sleeve technology

Adopts sleeve technology of plate cylinder and anilox roller (optional) to achieve fast job change.

Gearless drive system

Each printing station is driven by 8 servo motors to avoid gear wearing when running at high speed and accurate deck positioning. DH-ROC has a great job repeatability, it can record and recall data like register position, pressure setting and tension etc.

High efficiency drying unit

After printing, substrate goes up and pass the high efficiency drying unit to achieve high running speed. Cover of drying unit can slid out for substrate threading. Meanwhile, hot air is recycled to lower down power consumption.