As a novel advertising method, the paper cup is one of the most economical, affordable, and easy to operate advertising media because of its closeness to life and low cost. Flexographic printing is currently the main process used for paper cup printing; the print quality of paper cups depends to a large extent on prepress production. This article intends to analyze and explain some issues that should be noted during the production with paper cup printing machine.

First, the use of paper cups

1. Use of paper cups in beverage packaging

The most important function of a paper cup is to hold beverages such as carbonated drinks, coffee, milk, cold drinks, etc. This is its earliest and most basic purpose.

Drink cups can be divided into cold cups and hot cups. Cold cups are used to hold cold drinks, such as carbonated drinks, iced coffee, etc. Hot cups are used to hold hot drinks, such as coffee, black tea, etc.

Different from the cold cup, the surface of the hot cup is affixed with a special layer of polyethylene film, which not only has good heat resistance, but also is non-toxic and harmless under the immersion of high-temperature beverages.

2. Use of paper cups in advertising

At present, advertisers or manufacturers also use paper cups as an advertising medium.

Designing the pattern on the cup body can give people different drinking moods, and it is also a “symbol” for promoting a certain product. Because the product’s trademark, name, manufacturer, distributor, etc., can be designed on the surface of the paper cup. When people drink beverages, they can get acquainted with the information and understand the products. Paper cups provide a platform for people to understand these new products.

Second, compare the printing methods of paper cups

Paper cups have a variety of printing methods, and different printing methods have different printing characteristics.

1. Offset

Offset printing is based on the principle of using oil-water repulsion. Film propaganda paper cups are oil-resistant and water-resistant. The blank part is hydrophilic and oil-resistant, and the images are transferred to the substrate through a blanket cylinder. The advantages of offset paper cups are full, vivid, and high definition. No matter whether it is a gradual change or a fine and fine line, it can be clearly displayed, making the appearance of the paper cup more beautiful and more attractive to the eye of the customer. But offset printing is not suitable for printing edible paper cups, because offset printing inks are not very environmentally friendly.

2. Silk screen

Screen printing is flexible and flexible due to its flexibility and applicability. It is not only suitable for printing on soft articles such as paper and cloth, but also suitable for printing on hard articles such as glass, ceramics, etc., and is not limited by the surface shape and area of the substrate. However, the advantages of screen printing paper cups cannot be well represented, and screen printing has great restrictions on the reproduction of graphics and texts, and there are certain difficulties in dealing with gradation and reproducing image accuracy.

3. Flexo

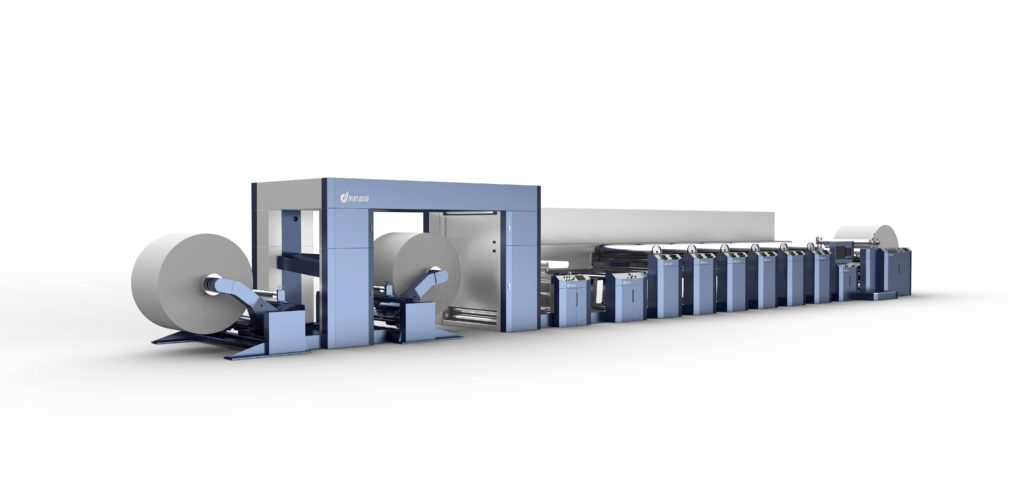

Flexo printing is called “green printing” due to the use of water-based inks. Many of the company’s product packaging are now developing toward flexo printing. Because the structure of the flexo printing machine is relatively simple, compared to the large body of the offset printing press and the high cost of materials, the flexo printing machine becomes “thin”. In terms of cost, the equipment investment of the flexo printing machine is lower than that of offset printing machines of the same scale, and generally can save as much as 30% to 40%. The small investment in production has attracted the participation of small-scale printing companies. Flexographic printing is not as narrow as the screen printing in the selection of originals, and the rules on color are relatively broad, but they are inferior to offset printing. Flexo printing is the main process currently used for paper cup printing. The print quality of paper cups depends largely on prepress production. However, because its environmental protection is green printing, the advantages of offset printing and offset printing are high.

If you need a good paper cup printing machine, please visit:

DH paper cup printing machine (flexo): http://www.donghang.cn/Product70/43.html