How to avoid abnormal pressure in flexographic printing press

When using a flexographic printing press, setting the proper pressure has a large effect on print quality. When the pressure is not correct, it may cause a series of problems, such as large registration errors and ink bar.

a. Flexographic printing press that exceeds the mechanical accuracy error shall be repaired to achieve the standard.

b. Control the ink pressure, the ink pressure should not be too large. In the ink dot where the ink pressure is too large, the ink color in a circle is uneven, half is shallow and half deep, or a small amount of ink overflows around the dot, and the dot with excessive printing pressure is a dot deformation. Becomes an ellipse. When the ink pressure is adjusted, it should be from light to heavy, the pressure is gradually added, and it cannot be overweight at once, and then returned. At this time, the printing plate is full of ink, including the concave area of the printing plate. This has not caused embossing has caused a hidden danger of blocking. After the ink pressure is added, the printing pressure is gradually added. After observing the printing pressure is normal, all the ink is printed everywhere, and the dot is not deformed. At this time, the ink pressure is slightly removed, and the printed matter is correct. The party will speed up again. If the ink pressure is too much, the hollow dot will appear on the printed product. At this time, the ink saturation will be different, but the blocking phenomenon will be greatly improved.

c. Adjusting the unevenness of the printing plate and the double-sided tape is to use a pad lithographic plate instead of increasing the printing pressure, which is an important concept in operation. The commonly used leveling measure is that the tape can be affixed under the solid version. Generally, the thickness of the single-sided tape is about 50-60 u. Under the network cable version, the shellac paint can be applied. The thickness of the coating layer is about 4 u, and the layer can be coated with several layers.

d. Abnormal deformation of the dots is buffered with a low-density double-sided tape. The double-sided adhesive has good elasticity, although the pinhole is easy to appear when printed on the ground, but it is the best choice when printing the wire, the dot is not easy to be deformed, and the recovery is good.

e. From the order of pressing the plates, it is necessary to select the pattern from the part where the number of hanging nets is small to the part where the part is gradually pressed, that is, in the convex part of the printing plate, from the low density part to the high density part. Gradually stressed. At this point the pressure change is gradual, not abrupt. If it is the opposite, the probability of blocking is greatly increased.

f. Pay attention to the uninterrupted vertical direction during layout. Due to the intermittent nature of the typesetting, the convex portion of the printing plate in the longitudinal direction always has a difference between the high and low positions, and the impact of the pressure will be regular. If the sides of the plate are added with equal width beading, the bead will wrap the entire plate, so that the impact of the pressure will be much reduced. Or staggered typesetting, so that the entire circumference does not have a completely low position, then the plate roller runs more smoothly and the impact will be smaller.

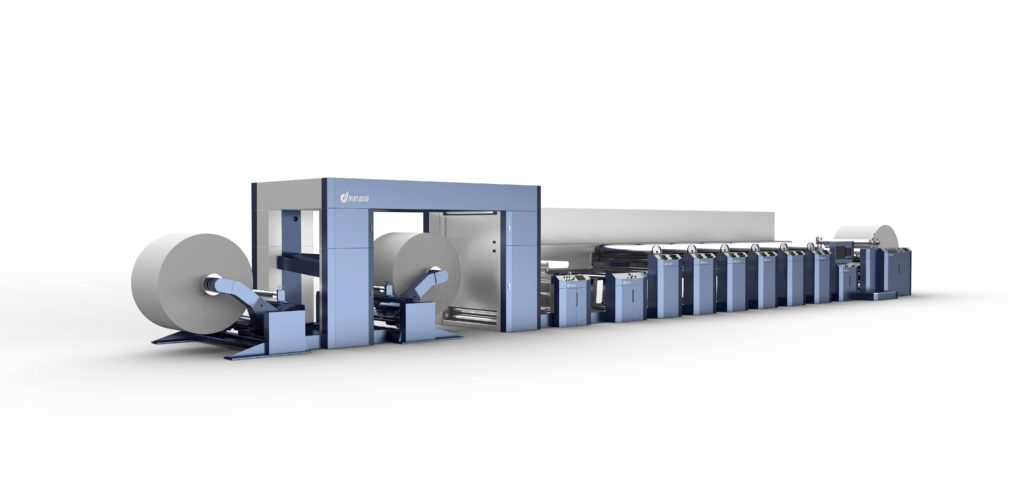

Over the past 20 years, DH has accumulated a wealth of experience in the design of flexographic printing press pressure structures to minimize the production waste caused by abnormal pressure.

DH OFEM CI flexographic printing press video: https://www.youtube.com/watch?v=9eUhy6zM1SE

DH ROC flexographic printing press video: https://www.youtube.com/watch?v=63t49psfFPs